Outstanding craftsmanship integrated with state-of-the-art technologies at the G-SHOCK "mother factory"

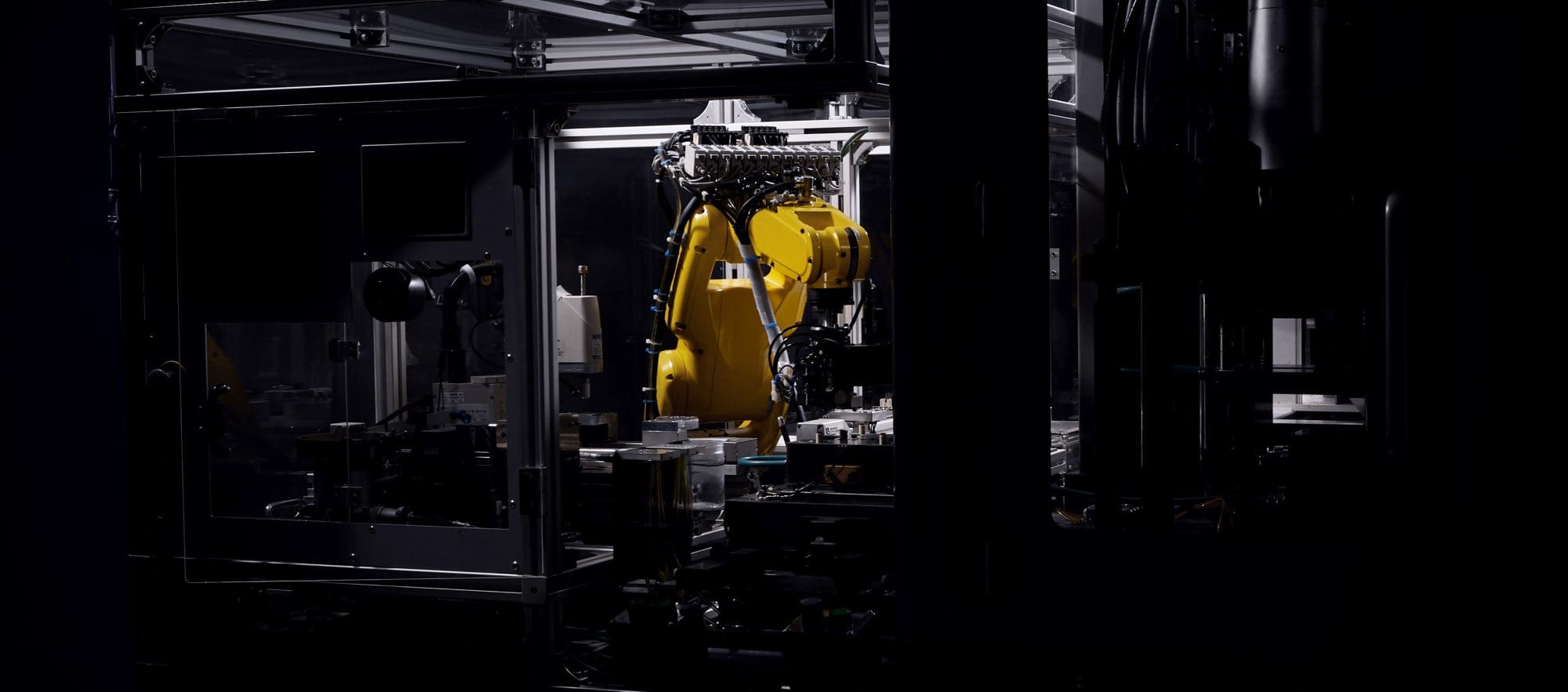

Surrounded by strings of peaks including the Zao and Kamuro mountains, Japan's Yamagata Prefecture is home to the Mogami River, which is known as one of the three swiftest rivers in Japan. This rich natural setting, with its fresh, clean air and pristine water, is home to Yamagata Casio, the "mother factory" of G-SHOCK. At this production facility, total consistency is maintained, from the manufacture of movements through to the assembly of cases, dials, hands, indexes, and bands. It also manufactures movement parts, dials, and other components using its proprietary mold technology.

Here, master craftspersons and engineers continue to challenge themselves and further hone their craft, inheriting the technical expertise and passion cultivated and maintained for over 40 years since the launch of the very first G-SHOCK. They generously apply their artisanal skills and state-of-the-art technologies to all stages of the watchmaking process, from manufacturing and processing to assembly and adjustment.

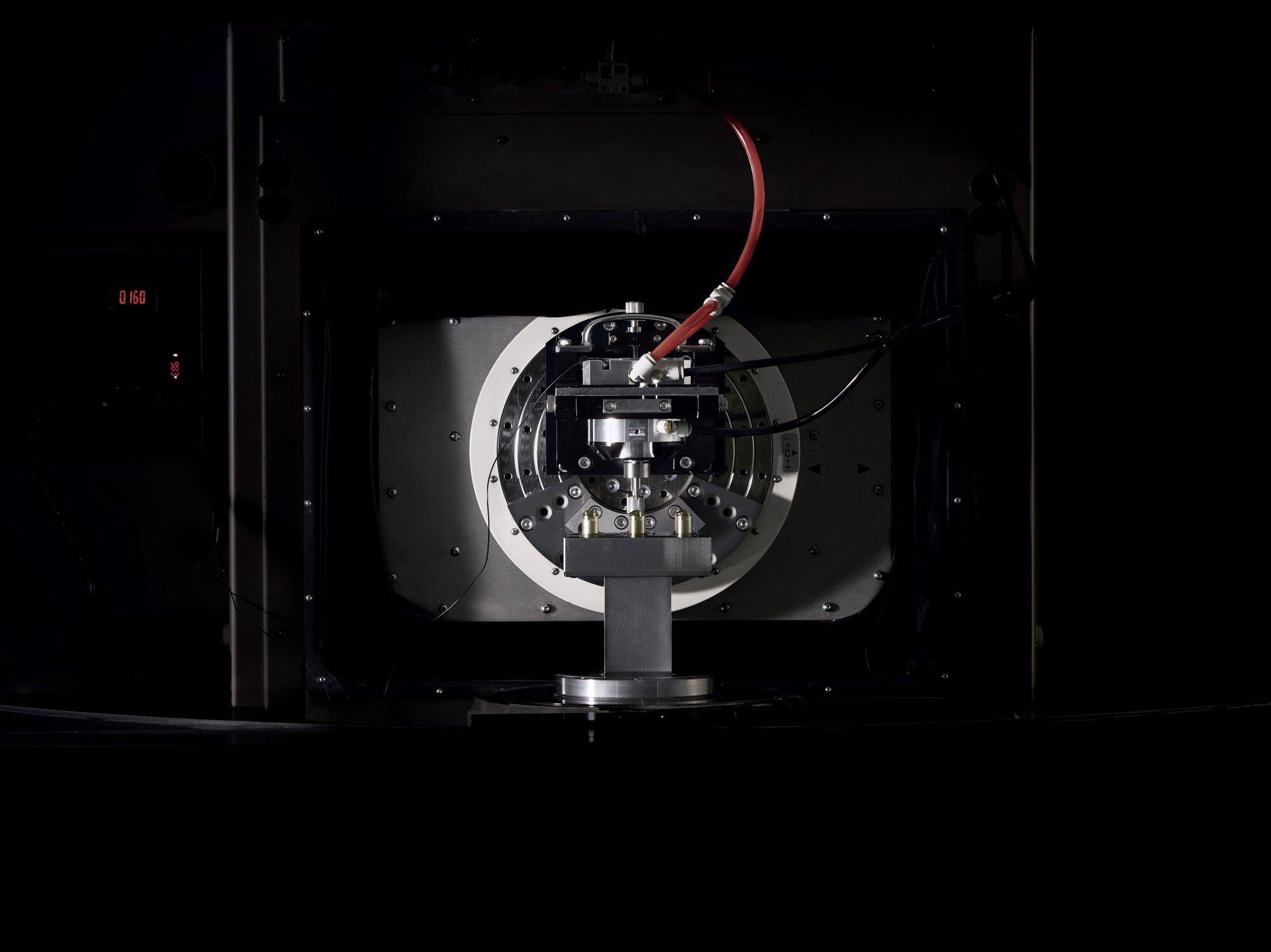

Watches are required to consistently maintain accurate timekeeping, unaffected by external elements arising from natural phenomena like temperature variations and vibrations. The experts responsible for the development and manufacturing of MR-G timepieces continue to create watches while making the most of the technology and expertise at their disposal to address the three greatest external threats to watches: shock, water, and magnetism.

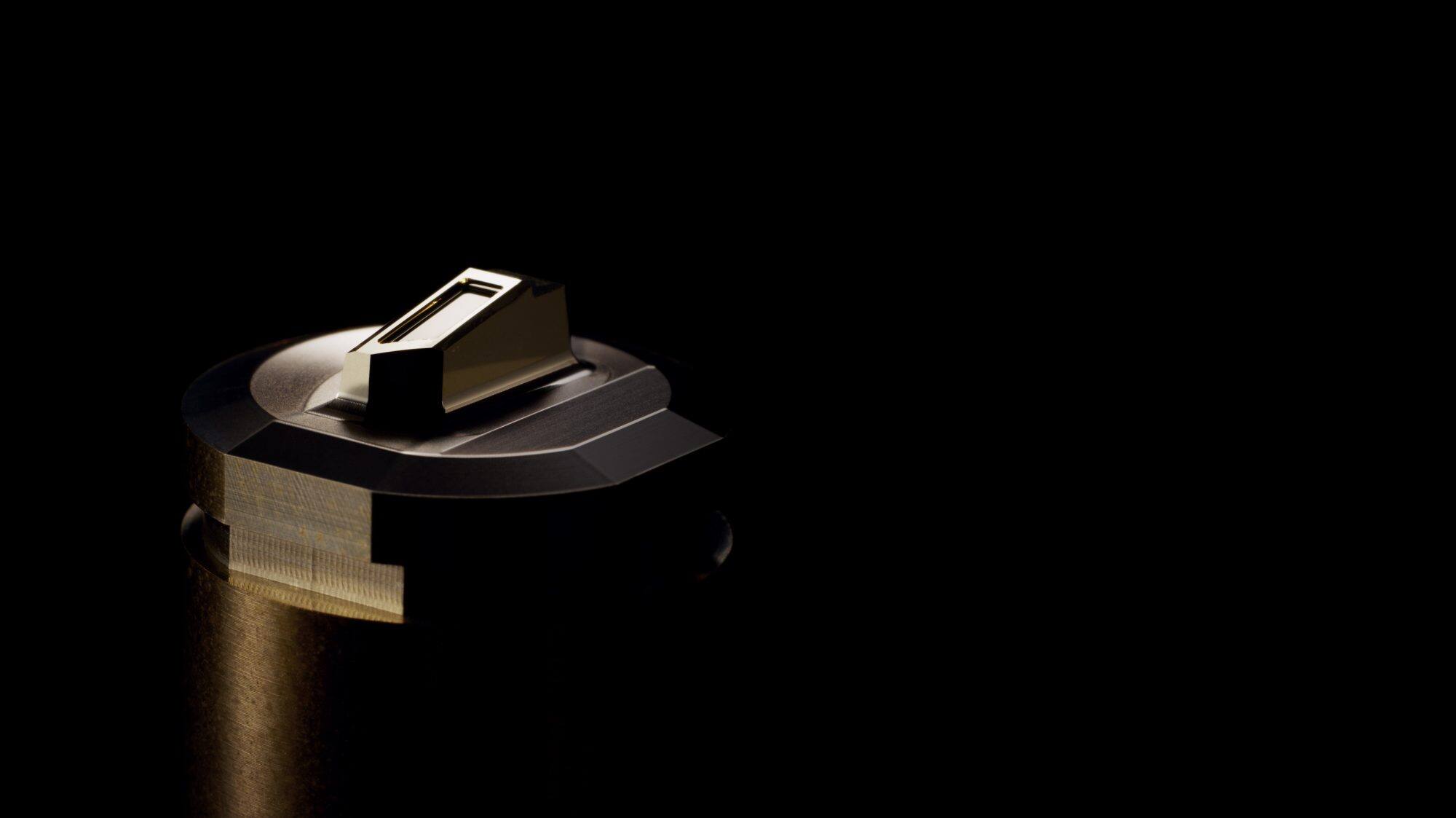

Yamagata Casio has been manufacturing die molds since 1985. After striving to make further improvements to its mold processing technologies, which directly affect the level of components' precision, in 2000, the facility succeeded in developing ultra-precision mold processing technologies. Since then, Yamagata Casio has been using molds manufactured with ultra-precision on the nano scale (1/1,000 μm). This technology is fully utilised for the flagship MR-G line, from the dial and its indices, which might be likened to the face of the watch, to the rotor at the "heart" of the movement, all the way to the stunning, distortion-free mirror finishes, intricate surface processing, and component shapes of the most finely detailed complexity.

Manufacturing minuscule gears

The movements in MR-G analogue watches are powered by our Tough Solar system, which applies pulse signals to the coil via a quartz oscillator. The magnetic force generated is converted into rotational force for the rotor by the stator, and the force is applied to the gears and hands, in that order, to produce the precise movement of the hands. Movements in multi-hand MR-G timepieces incorporate up to six of these stepping motors. A dual-coil motor with two coils is used to turn large, heavy hands and achieve high-speed forward and reverse rotation.

The rotor, or "heart" of the movement, measures a mere 1.1 mm. Crafted with a manufacturing process at Yamagata Casio featuring superior precision processing technologies, the rotor not only transmits conserved power efficiently, but also minimises friction, helping to extend the service life of components at the same time. MR-G timepieces are driven by a passion for practicality, toughness, and beauty at the highest level, using both metal and reinforced resin materials with superior durability to suit the purpose.

*1 Tough Solar, the original Casio solar-charging system, generates power not only from sunlight, but even indoor light sources such as fluorescent lamps.

*2 The stator, rotor, and coil are components of the stepping motor which moves the hands.

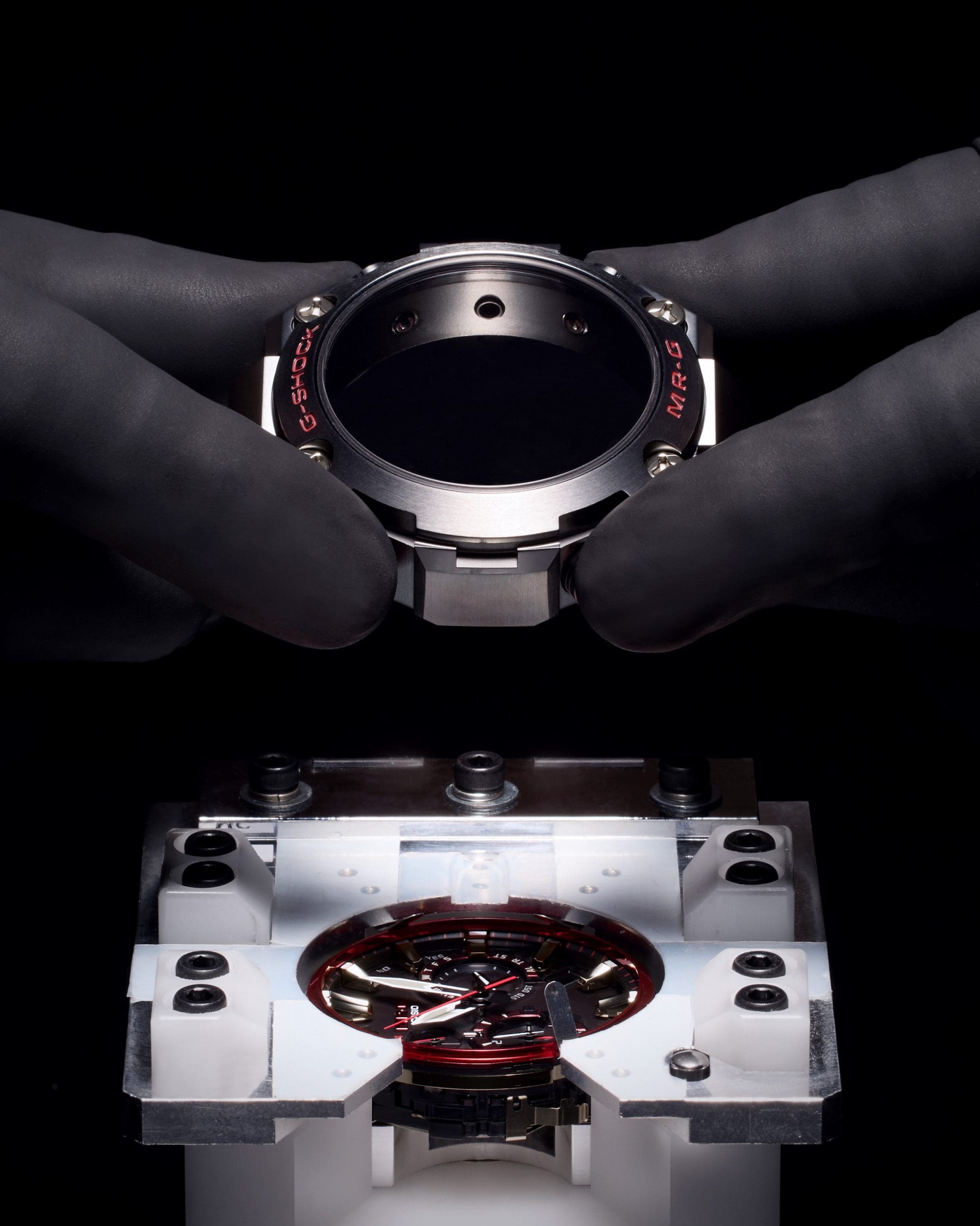

Meticulously assembled movements

All MR-G movements are manufactured at Yamagata Casio. The movements are assembled by engineers with meticulous attention to detail in every stage of the process, from selection of precision components to fine adjustment of the mounting position to enable the precision meshing of the gears, to inspection. MR-G movements assembled in this exacting manner deliver high degrees of shock resistance. Featuring an automatic correction function as well, they enable independent rotation of the hands on the dial to maintain precise time with speedy and smooth rotation.

Meticulously assembled movements

All MR-G movements are manufactured at Yamagata Casio. The movements are assembled by engineers with meticulous attention to detail in every stage of the process, from selection of precision components to fine adjustment of the mounting position to enable the precision meshing of the gears, to inspection. MR-G movements assembled in this exacting manner deliver high degrees of shock resistance. Featuring an automatic correction function as well, they enable independent rotation of the hands on the dial to maintain precise time with speedy and smooth rotation.

Superior water resistance: the result of painstaking control

The superior degree of water resistance delivered by MR-G timepieces is the result of the specialised technologies for which Yamagata Casio is known. At this special facility, experts in each field pour their expertise and energy into each stage of the process, from manufacturing and processing to assembly and adjustment. The indoor environments in which they work are meticulously controlled as well, from the degree of air cleanliness to the humidity and other factors.

At the completion of the lengthy watchmaking process, all MR-G timepieces are subjected to two different water-resistance tests, one using air pressure and the other using water pressure. Yamagata Casio experts conduct this testing with supreme confidence, backed by their record of meticulous control at every step of the process and their continuous history of commitment to quality.

The high degree of water resistance delivered by MR-G timepieces is a crystallisation of the sincere approach each individual artisan and engineer at Yamagata Casio takes to every aspect of their work. Exuding endless passion for ultimate strength, beauty, and practicality, the MR-G line continues to evolve, delivering not only shock resistance—the proof of its toughness—but water resistance as well.

Yamagata Casio utilises ultra-precision processing technologies for the die molds used for watch parts. While the level of machining precision required for the timepieces' components is 1/1000 mm, in cutting the die molds for metal components used in more decorative aspects of watch design, ultra-precision machining on the nano-order (1/1000 μm) is required for cutting processes. Once the parts have been processed with this meticulous attention to detail, they are assembled one by one by Yamagata Casio's mold craftspersons, who make minute adjustments to produce the beautiful dials uniquely befitting the "Made in Yamagata" designation.

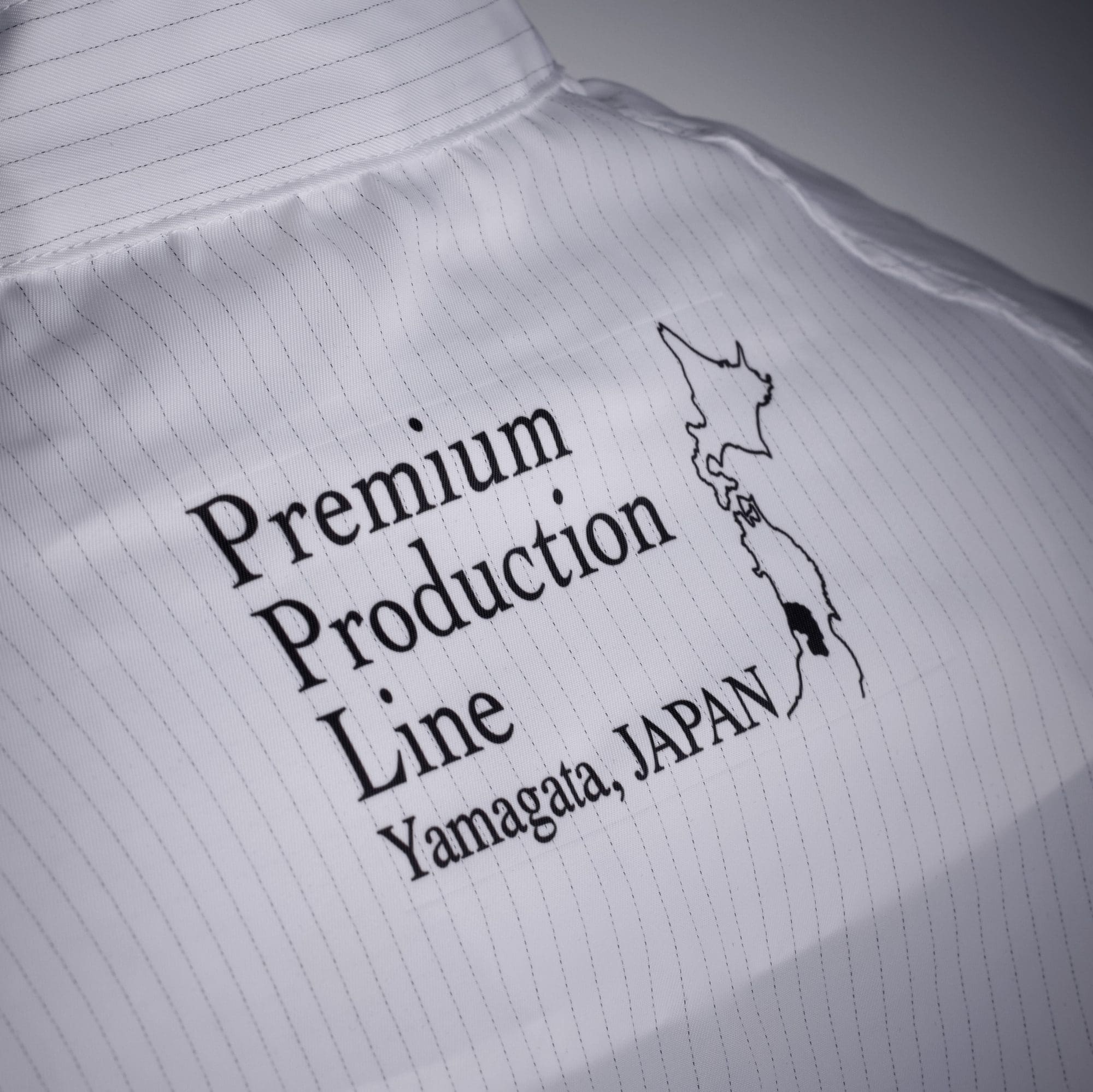

Premium Production Line

Integrating finely honed skills and sensibilities with digital engineering

MR-G timepieces are manufactured at the Yamagata Casio high-end Premium Production Line (PPL). In charge of this special line are highly skilled "Medallists" certified in accordance with rigorous criteria stipulated by Casio. These elite workers, who maintain the highest degree of technical proficiency, employ their finely honed skills and sensibilities, together with precision digital engineering, to craft each component. Their extreme passion and attention to every detail, worthy of the flagship line of the G-SHOCK brand, drives the creation of products with ever higher degrees of perfection.