GBDH2000 bio-based resins:

The use of resins from castor seeds and corn help reduce environmental impact and lead to a better circular economy.

Carbon-neutral bio-based resins have the potential to curb the rising CO2 concentration in the atmosphere. They are widely believed to help mitigate global warming and reduce dependence on fossil resources. Let's take a look at the cutting-edge world of bio-based resins, where familiar plants are turned into plastics.

Use of bio-based resin

GBDH2000 G-SHOCK MOVE

Model Selection

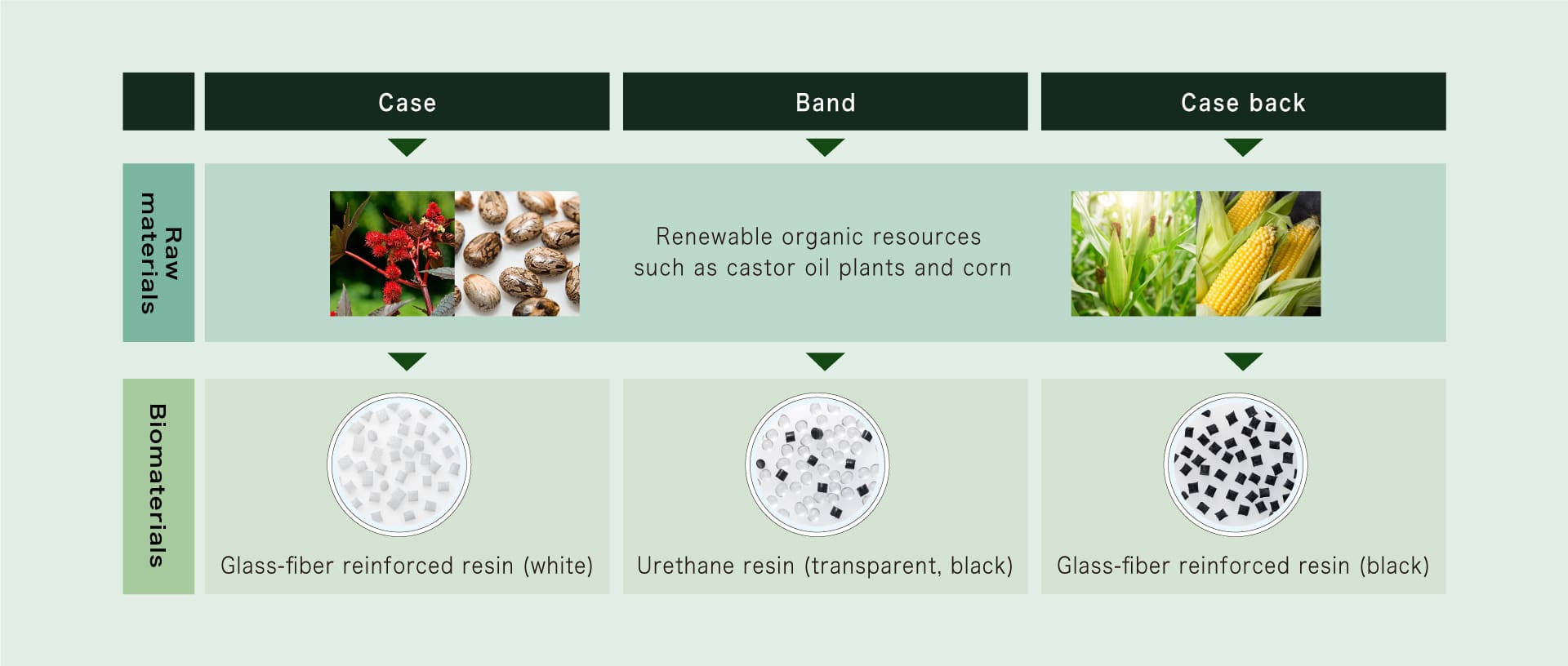

The GBD-H2000 G-SHOCK MOVE watches listed below contain bio-based resin in the case, case back and soft urethane strap. By using materials derived from renewable organic resources, eco-based plastics can help reduce environmental impact by reducing CO2 emissions.

Bio-based resin

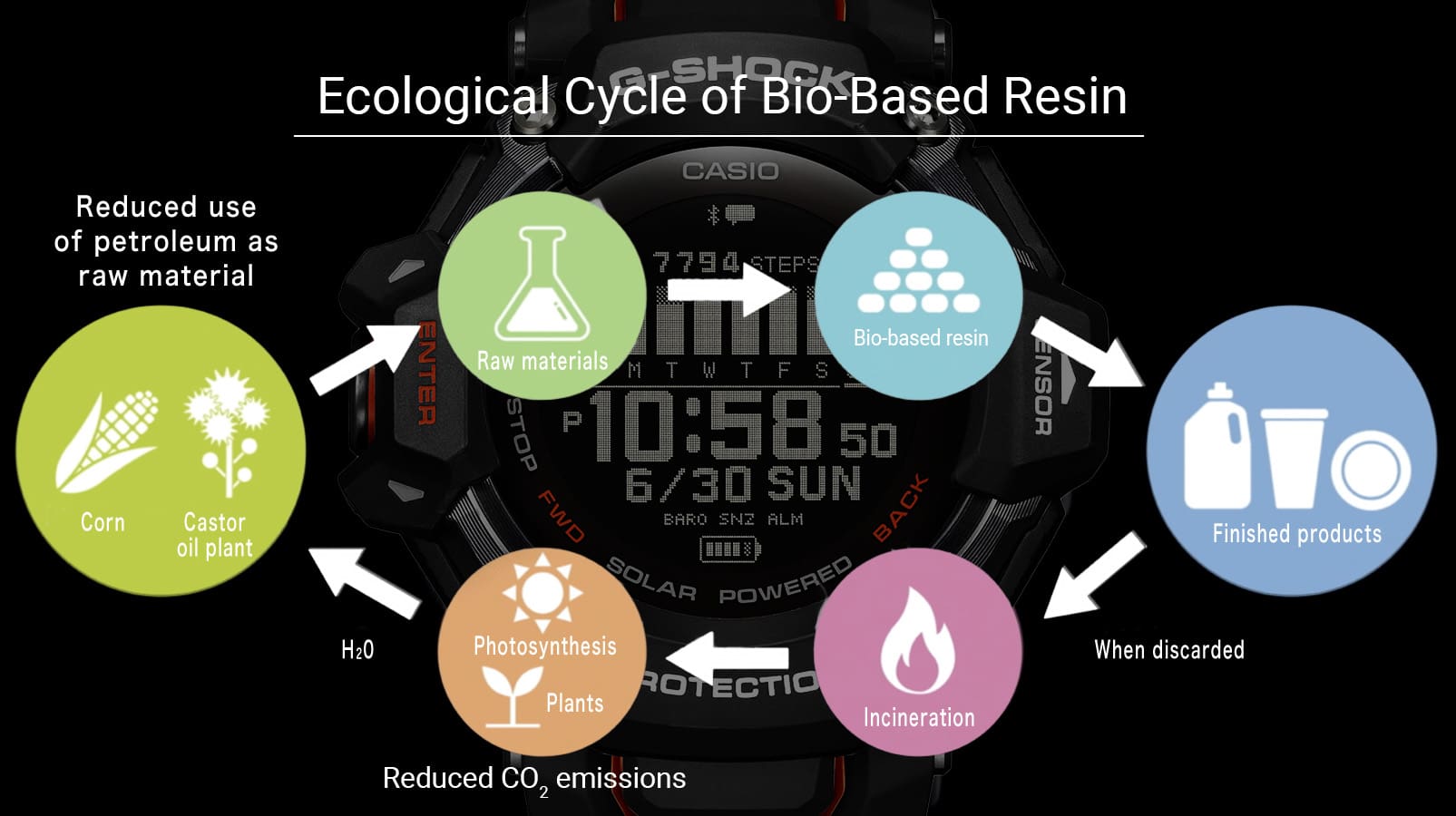

Bio-based plastics are polymers produced by the chemical or biological synthesis of materials derived from plants or other renewable organic materials. They are widely believed to help reduce environmental impacts and promote the transition to a circular economy. G-SHOCK uses bio-based resins derived from castor seeds and corn.

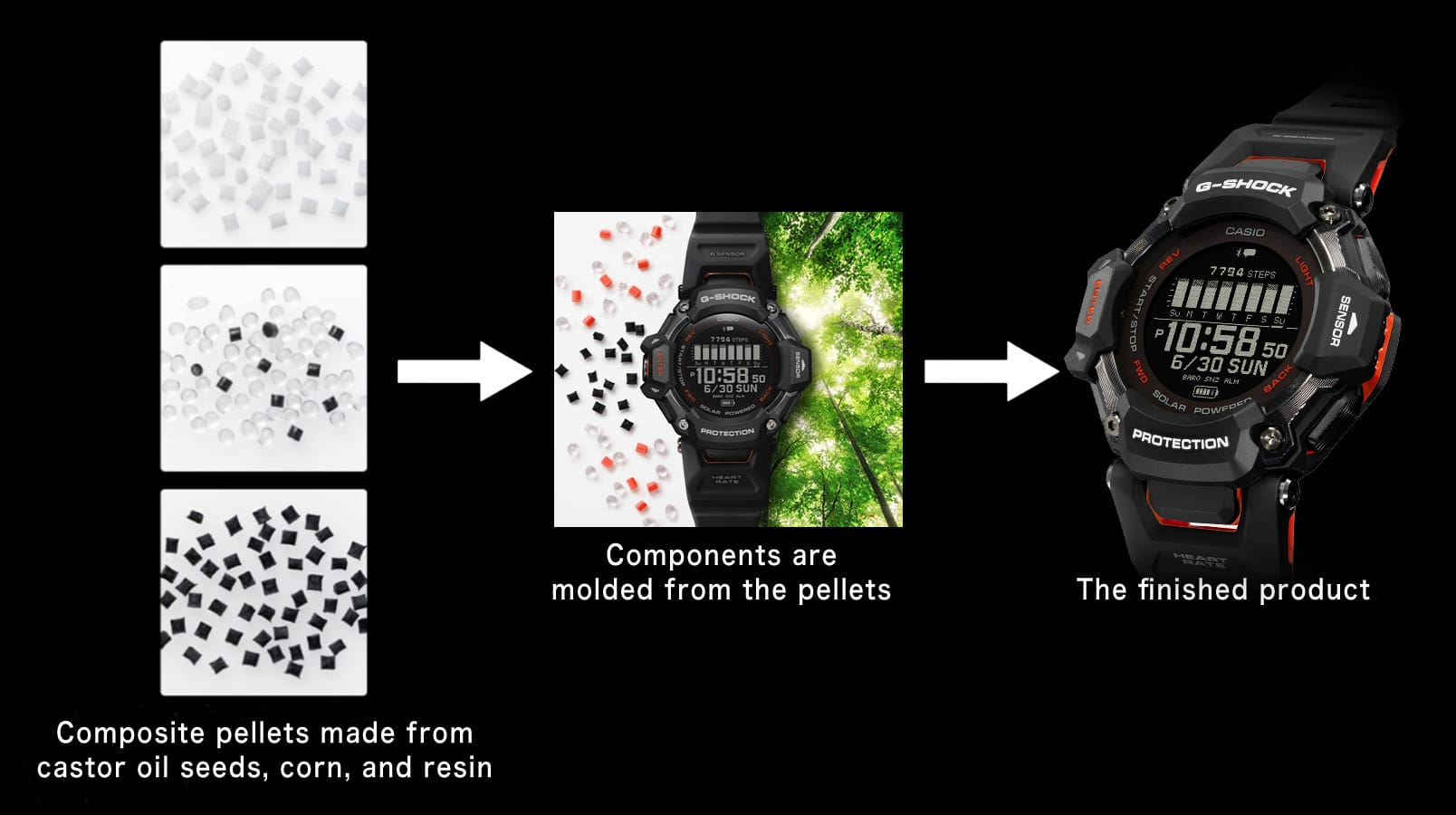

The GBD-H2000 G-SHOCK MOVE watches use bio-based resins derived from castor seeds and corn.

The biomass used as raw material binds carbon (CO2) from the atmosphere during its growth. This means that when biomass is burned, there is no net increase of CO2 in the atmosphere as long as the biomass grows back. Accordingly, we assume that the use of bio-based resins produced from biomass will help reduce CO2 emissions. In addition, because they are made from renewable organic resources, they can help reduce the use of exhaustible resources, including fossil resources.

The components obtained from plant materials are pelletised and used to mould watch components such as the case, strap and case back. The use of these refined materials for moulding allows the production of products with consistent quality.