Core technologies supporting G-SHOCK’s pursuit of toughness

DW-5600: Shock resistance test with a hammer

MR-G: Shock resistance test/Shattering

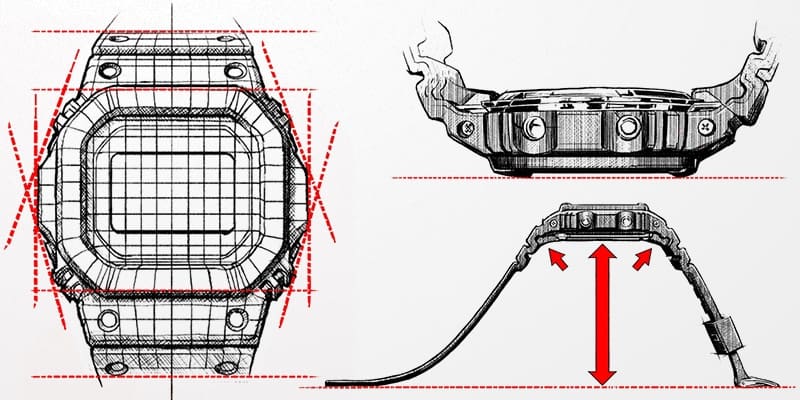

All-directional covering

If the watch is dropped, the protruding bezel fully enclosing it absorbs the shock, protecting the buttons directly connected to the module and alleviating shocks from all directions. The bezel also guards the surface of the crystal. The strap is curved stiffly at the point of connection with the case, moreover, enabling it to serve as a shock absorber and prevent direct shocks to the back of the case.

Protective cushioning of key parts

The crystal oscillator and other critical parts inside the module are guarded individually by cushioning material. Any strong shock to the watch causes immediate distortion of the cushioning inside the module, preventing contact failure and malfunction.

Hollow case structure

The proprietary case structure leading to the birth of the first G-SHOCK

Based on the realisation that "shocks are not transmitted inside a bouncing rubber ball," the structure was designed to allow the module to float inside the case and absorb shocks transmitted from the outside. Today, the module’s shock resistance is realised through further technical innovations. But the revolutionary tough structure that gave G-SHOCK its origin began here.

Square original design (5000/5600 series)

We retained the original G-SHOCK’s square design while at the same time pursuing universal utility in everything from the internal design, including the module structure and LCD, to such exterior design features as the materials, size and shape. The proud original shape has been passed down without change through the 5000/5600 series as a symbol of G-SHOCK.

- DESIGN: Minimalist design with impeccable shock resistance

- LCD SIZE: With an aspect ratio of 16:10, oriented close to the human viewing angle

- FORM: A perfectly balanced shape that does not affect the wearing in any way