Ever since the advent of G-SHOCK more than 40 years ago, the brand has upheld an unyielding spirit of toughness. Today, MR-G timepieces stand at the pinnacle of this legacy, seamlessly blending cutting-edge technology with the delicate sensibilities of Japanese craftsmanship. Every MR-G is a masterpiece of refinement, born from the relentless pursuit and expression of audacious creativity.

In “Making Art with MR-G,” we are commissioning contemporary artists to create pieces that incorporate MR-G timepieces crafted with signature combinations of tradition and innovation. The project explores this dialogue, asking artists to fuse their creative vision with the essence of MR-G. The articles showcase the inspiration that guided each of the artists as they applied their creative sensibilities to give form to the philosophy inherent to MR-G in their own unique way.

This first installment features Genta Ishizuka, an artist who works with organic three-dimensional forms he creates using lacquer. Presented with the MRG-B2100B — an embodiment of strength and precision — he embarks on a journey to reimagine time through his art.

Genta Ishizuka: The Tactile Allure of Urushi Art

Artist Genta Ishizuka employs traditional Japanese urushi lacquer crafting techniques to create organic, three-dimensional work. Wrapped in lustrous lacquer-treated membranes suffused with a sense of depth, his pieces exude dynamic energy, as if they might just spring into motion at any moment.

“Urushi lacquer, originally derived from tree sap, is a material imbued with a fascinating, talismanic sort of charm. Through my work, I hope to stimulate people’s tactile sensibilities and conjure up new sensations for them that had previously remained concealed,” the artist explains.

Coming into contact with contemporary art in the course of studying urushi lacquering at Kyoto City University of Arts, Ishizuka tried his hand at creating original artwork with lacquer. In exploring modes of expression and seeking to bridge the distance between himself and lacquer, eventually he arrived at working with everyday items. Employing the traditional raden mother-of-pearl inlay technique, typically used in lacquerware decoration, he experimented instead with embedding cutter blades and staples into the lacquered surface.

“From an early age, I always liked crafting things out of familiar items from day-to-day life. My desire to make artwork with lacquer, I felt, was an extension of something like that.”

To further emphasize the depth and tactile quality of urushi lacquer, Ishizuka expanded his artistic approach from two dimensions to three. He sought to create tension using lacquered membranes, drawing inspiration from the shapes found in everyday life — such as the tightly woven mesh of a fruit bag or the bundled ducts of an air-conditioning system. Taking a hint from these shapes, he developed a process — first making a prototype, then covering it with an elastic cloth, and finally applying layers of lacquer.

“Like the crafting I just mentioned, I play around with materials, exploring their forms, then create membranes to cover them with. That entails applying many coats of lacquer and polishing them. I explore ways to create finished pieces where eventually the emphasis is on the actual material more than my intention as the artist — pieces that stand on their own in an unforced way.”

The approach makes Ishizuka’s pieces positively brim with a vitality that is astonishing for objects and materials that were originally inanimate. His mode of expression, born of a passion for highlighting the textural essence of lacquer, has an intensely stimulating effect on tactile sensations.

What sort of perspective would Ishizuka bring to MR-G? We presented him with an MRG-2100B, the focus of this current feature, to see what he might think.

“It’s metal-crafted with a really solid feel. I had always thought G-SHOCK watches were made of resin. This makes me very curious about the manufacturing process. Could I visit the production facilities for some inspiration?”

Genta Ishizuka

Born in Kyoto in 1982, Genta Ishizuka participated in an exchange program at the Royal College of Art, London, before graduating with an MFA in Urushi Lacquering from Kyoto City University of Arts in 2008.

Ishizuka creates works that project notions of boundaries and physical awareness onto the lacquered surfaces formed by urushi. A natural sap derived from trees, urushi demands a form that befits its essence. Through his practice, Ishizuka seeks to explore the dynamic interplay between human gestures and the material, forging new relationships and spaces where the two converge.

Significant exhibitions include “The Future of Artisanal Beauty” (Warehouse TERRADA, Tokyo / Kennin-ji Temple, Kyoto, 2024), “LOEWE Lamps” (Palazzo Citterio, Milan, 2024), and “Visionaries: Making Another Perspective” (a special exhibition at Kyoto City KYOCERA Museum of Art, Kyoto, 2023). In 2025, he plans to hold a solo exhibition at ARTCOURT Gallery.

Significant awards include the Kyoto Prefectural Culture Award’s Encouragement Prize (2024), LOEWE FOUNDATION Craft Prize (2019), and Kyoto City New Artist Award (2019).

A Face-to-Face Encounter with State-of-the-Art Production Technologies at Yamagata Casio

Ishizuka set out to see Yamagata Casio for himself. This G-SHOCK “mother factory” handles all phases of the MR-G watchmaking process, from movement production to assembly. It even manufactures movement parts, dials, and other components, using highly innovative, proprietary molding technologies.

The manufacturing process for the rotor — the “heart” of the movement that powers an MR-G — was the first thing that really awed him. Measuring just 1.1 mm, the rotor is astonishingly tiny. The intricate processes employed to mold parts of this size are performed entirely by robots — and in a production environment that is typically unlit and pitch-dark.

“For me, I need illumination to see what I’m doing with my hands, or I can’t make anything. Come to think of it, I guess it makes sense that robots would be able to make things without that kind of visual input.”

After changing into a dustproof suit, he had a look at the movement assembly process. Orderly rows of machinery lined the broad, white space, with workers performing checks here and there. For this process, human workers collaborate with the automated machinery, inspecting the assembly work of intricate components carried out by the robots. Highly skilled “Medalists” certified in accordance with rigorous criteria stipulated by Casio then handle the rest of the MR-G assembly process, using these completed movements.

“I had always imagined there would be some kind of dividing line between things made by hand by people and things made by machines, but this feels like a place, here at Yamagata Casio, where the boundaries between human workers and machinery aren’t so distinct — like there’s a harmonious collaboration of the techniques and skills they each possess. It made me think of a single, big life form of some kind, specialized in creating watches. This was the first time I’ve ever visited a manufacturing facility like this, getting to really see how high-precision components are reproduced so consistently with my own eyes. Somehow, it even makes me think of the music video for Björk’s All Is Full of Love, directed by Chris Cunningham!”

Before visiting Yamagata Casio, Ishizuka had actually stopped by the Toshio Kashio Memorial Museum of Invention in Tokyo, as well, he mentioned.

Drawing on his impressions from the museum, he went on, “I learned about how the original G-SHOCK was based on a one-sentence proposal and about the experiments Kikuo Ibe carried out, dropping prototypes out the building’s window. The process up to that point felt familiar to me, like the way I approach my own work. From there, though, the difference is whether you focus on consistently reproducing high-quality items or creating one-of-a-kind art pieces. I could really relate to what I saw there up to a certain point. That was fascinating to me.”

Leaving us with these impressions, Ishizuka went to get back to work at his own studio.

Expressing Toughness with Lacquer Layering

Visiting Ishizuka at his studio in Kameoka, Kyoto Prefecture some six months after commissioning work from him, we found his finished piece displayed on a table. With its lustrous, jet-black finish, it was mineral-like, ore-like, exuding a striking sense of presence. Appearing decidedly weighty, yet somehow suggestive of softness, it projected an intriguingly curious look and feel.

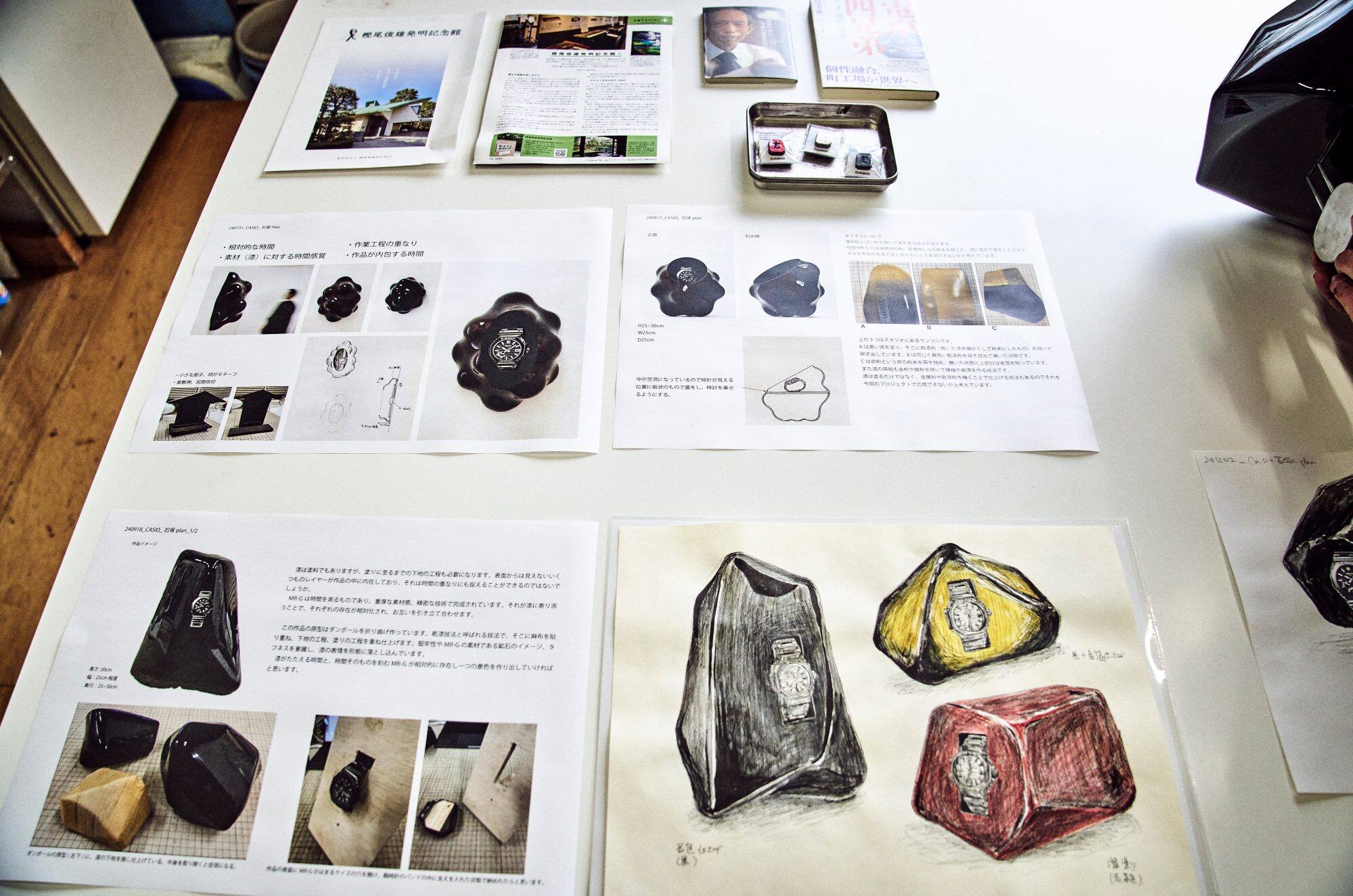

His work was surrounded by various studies of G-SHOCK, bundles of sketches, maquettes (or mockups of molded forms), samples of lacquer finishes, and so on. We asked Ishizuka what he had in mind when working on the piece.

“When I picked up the MRG-B2100B, I sensed toughness, intricacy — precision crafting in a solid, densely concentrated form. Getting to visit the production facilities confirmed that for me. So, what approach could I take to a piece of culturally oriented art to complement a watch crafted with such high-precision technologies? I got the idea of juxtaposing the tactility of the lacquer with the impression the watch gave off in a relativistic way.”

Initially, he envisioned a piece suggesting a hokora, or miniature wayside shrine, in an organic form housing the MRG-B2100B. In consideration of the metal watch’s textural sophistication and toughness, however, he rethought his approach, eventually arriving at a form suggesting a type of mineral or ore.

“I considered how to express the relationship between materials — such as COBARION, a state-of-the-art alloy used in the MRG-B2100B, and lacquer, which I work with — and also between the precision of a timepiece and the expansive sense of time contained within my artwork. I also wondered if the process of repeatedly layering lacquer could itself be seen as an accumulation of time. This idea sparked my vision of creating a ‘time ore’ with lacquer.”

The structure takes shape by bending the base material into a closed form. “By merging the rigid, mineral-like presence with the fluid expression of lacquer, I sought to create a piece that was both solid and soft,” Ishizuka explains. The result is a form where geometric precision and organic movement coexist, unified by the deep, lustrous surface of urushi — all echoing the substance of the MRG-B2100B itself.

The work employs the dry lacquer technique (Kanshitsu technique), in which a layer of hemp cloth is first applied, then hardened with lacquer, and finally additional layers are repeatedly applied to increase the strength. Each stroke, each polished layer, captures a dimension of time as only the artist’s hand can. Finally, he applies a roiro finish, a technique used to further polish the upper lacquer surface to a mirror-like gloss, giving the piece a jet-black tone expressing toughness. The finished piece is imbued with a sense of depth achievable only with these processes of hand-crafting, applying multiple layering and polishing.

“I do make initial sketches, but I usually start out by creating pieces as if I’m crafting prototypes or mockups. Applying multiple layers of lacquer and polishing them reveals various things to me, like different textures that can be brought out in the material. I’m never quite sure how a piece is going to turn out until it’s finished.”

The lustrous jet black that eventually came out in the surface of the piece seems imbued with time in a myriad of forms. Peering into it can feel like staring into an abyss of unfathomable depth, suggesting a sense of infinity that even evokes the whole cosmos.

A Harmonious Resonance Between Time and Craft

The concept of artisanal craftsmanship is something Ishizuka deeply values in his approach to making art. He sees in it a historical background rich with the accumulated wisdom of a long line of predecessors who sought to make people’s lives more comfortable and pleasant with their crafting traditions.

“I believe craftsmanship is fundamentally about transforming natural materials into something that enhances our experience — turning raw elements into forms of comfort and refinement. It is the ingenuity it takes to shape clay into vessels and fire them, or to use sharpened stones to cut wood, or to coat objects with urushi lacquer. These processes, born from an instinct to refine the raw and wild, have evolved into the techniques and tools we rely on today. Drawing from this accumulated wisdom, my work seeks to engage the sense of touch, evoking a deeper, more primal connection with materiality.”

The concept of time that the MR-G timepieces embody was also born in the quest for greater convenience in people’s lives. The early evolution of timepieces began with the sundial, which used the position of the sun in the sky to tell time, followed by water clocks, which used the flow of water to measure time. Analog clock-making technologies brought the advent of clock towers and other clocks, and finally came watches compact enough to be worn on a person’s wrist. G-SHOCK development went a step further, realizing the vision of “a watch that wouldn’t break even if dropped.” Today, the flagship MR-G line continues to pioneer ever greater heights of pleasure and joy. At the heart of this trajectory is the crystallization of artisanal crafting technologies.

With the MRG-B2100B displayed on it, Ishizuka’s piece forms a new visual together with the timepiece. The lustrous mass of lacquer suggests a type of mineral or ore representing a crystallized accumulation of time. Floating out from the piece, the MR-G ticks away the time with impressive precision. The radiant sheen of the COBARION material seems to resonate with the jet-black lacquer, creating a singular, harmonious beauty in their pairing.

“Japan is home to a time-honored culture of suiseki appreciation. These are artistic displays that might consist of a found stone with an intriguing shape set in a shallow water basin or on a stand, suggesting the shape of a mountain peak, perhaps, or Kannon, the Buddhist Goddess of Mercy. With my piece as well, though I don’t have a specific image in mind, I hope viewers might find something that appears to them out of it in the same sort of way.”

A Singular Vision Pairing Different Senses of Flowing Time

“Applying countless layers of lacquer and polishing them, I’ve created a jet-black, ore-like mass that flows with a sense of time existing in a relative relationship with the sense of time represented by the precision timekeeping of the MRG-2100B. While these differing senses may stand in distinction to one another, I feel their pairing presents a singular vision to be taken in.”