Secrets behind the unparalleled quality of MR-G timepieces — Over 200 test points

MR-G, the flagship G-SHOCK line, delivers the toughness to keep operating in any kind of challenging environment. Ensuring this level of reliability requires MR-G timepieces to undergo many different tests to ensure that they satisfy stringent criteria. We asked Ryosei Agari of the Hamura R&D Center to share some of the secrets behind the uniquely rigorous — and sometimes downright extreme — assessment specifications for the testing Casio performs.

Ryosei Agari

Hardware Quality Assurance Section-12, Hardware Quality Assurance Department-1, Quality Assurance Unit, Development Headquarters, Hamura R&D Center

“What does it take to break a watch?”

The tireless pursuit of ultimate toughness, with continuous updates and innovation

Watches were originally considered delicate precision instruments never to be dropped. But the tough ness of G-SHOCK, born in 1983, has a history of bold durability testing that began with the dropping prototypes from a third- floor window at the Hamura R&D Center. Over time, the pursuit of the ultimate quality spurred the creation of the brand’s flagship line, MR-G. Meanwhile, testing methods evolved alongside the watches to yield today’s remarkable level of quality. Tell us about this relentless pursuit of toughness.

“Our system of assessment, in the form we have in place today,” Agari explains, “dates to 2001. That’s when we began systematically managing the assessment framework with a focus on standardization, drawing on our accumulated knowledge and expertise in recognition of official standards.”

The quality assurance division at Casio, he declares, uses “aggressive quality assurance.” The quality assurance team is involved from the early stages of development, devising and initially implementing tests while providing feedback on areas for improvement. This ensures that every product meets exacting Casio quality standards.

About 100 assessments are performed in accordance with the watch concept, out of over 200 total specifications. Tests include drop impact and hammer impact testing for shock resistance; water-resistance testing; high-temperature, low-temperature, thermal shock, and moisture-resistance testing against temperature and humidity environment standards; and artificial sweat and saltwater testing to assess corrosion resistance.

MR-G has some of the highest standards among G-SHOCK watches. Even assessments that are performed on other models often require higher scores. This is because, among other reasons, MR-G watches incorporate refined design and advanced technology, which demand a higher level of quality. Additionally, the warranty period is set longer than that of other G-SHOCK watches, which means stricter requirements must be met.

Agari says the quality assurance for the MRG-B2100 posed particular challenges due to its latticework dial, inspired by traditional Japanese kigumi woodwork. The highly unique, intricate dial design, featuring numerous openings, made it especially difficult to control the resin injection molding processes, causing molding defects during the initial development. A repeated process of trial and error eventually led to success in achieving a level of quality befitting MR-G exterior design. This process included special flow analysis and redesigning the metal molds. As MR-G design continues to evolve, assessment specifications and quality criteria are frequently updated. This is one of the keys to crafting watches with the beauty, sophisticated gleam, and distinction users have come to expect of MR-G, as the flagship G-SHOCK line.

“Many unconventional watch concepts and unprecedented designs are proposed in the development of MR-G timepieces and other G-SHOCK watches. Highly innovative ideas, however, often come with multiple new quality concerns. When issues arise, it would be easy for us in the Quality Assurance Unit to reject these new ideas to prevent problems in the future,” says Agari, “but we don’t.”

“That’s because solving these concerns is absolutely essential — not only to satisfy G-SHOCK fans worldwide but also to attract new fans. We constantly explore how to deliver technologies that meet the exacting quality standards of MR-G and carefully identify the quality assessments we need to secure them. We look at the current level of high quality as just another milestone in the never-ending pursuit of true ‘MR-G quality.’ We do face some pressure, as the last bastion protecting the brand’s value, so each day brings new challenges, making the work both rewarding and exciting. I stay motivated and truly enjoy what I do.”

Aggressive quality assurance also means looking ahead to the future. In many industries and fields, leveraging big data for work efficiency and business proposals is becoming the norm. Agari says he hopes to further integrate data utilization into the development of quality criteria and assessment methods moving forward.

“While we incorporate customer needs into product development and the formulation of quality criteria, many ‘silent customers’ in the market do not directly share their opinions with companies. I hope to extract such quality-related data that exists abundantly in society, identify quality demands in advance, and prevent potential issues — ultimately contributing to the maintenance and growth of brand value.”

Recently, engineers have had more opportunities to speak directly with G-SHOCK fans, for instance at events for the general public at the Hamura R&D Center and guided tours of the Yamagata Casio factory.

Agari feels this kind of communication can drive the development of products that they love even better. Direct interaction with fans can help him and his team define assessment specifications that capture what “toughness” means to G-SHOCK fans, thereby co-creating new value with users.

Talking with fans, I’d love to ask, for example, what sort of toughness they might envision for a watch built to withstand journeys into outer space — even if that might be in the distant future. And on our side, too, what kind of risks might that entail? What kind of assessments would be required? It’s challenging just to consider, but it would be very rewarding work.”

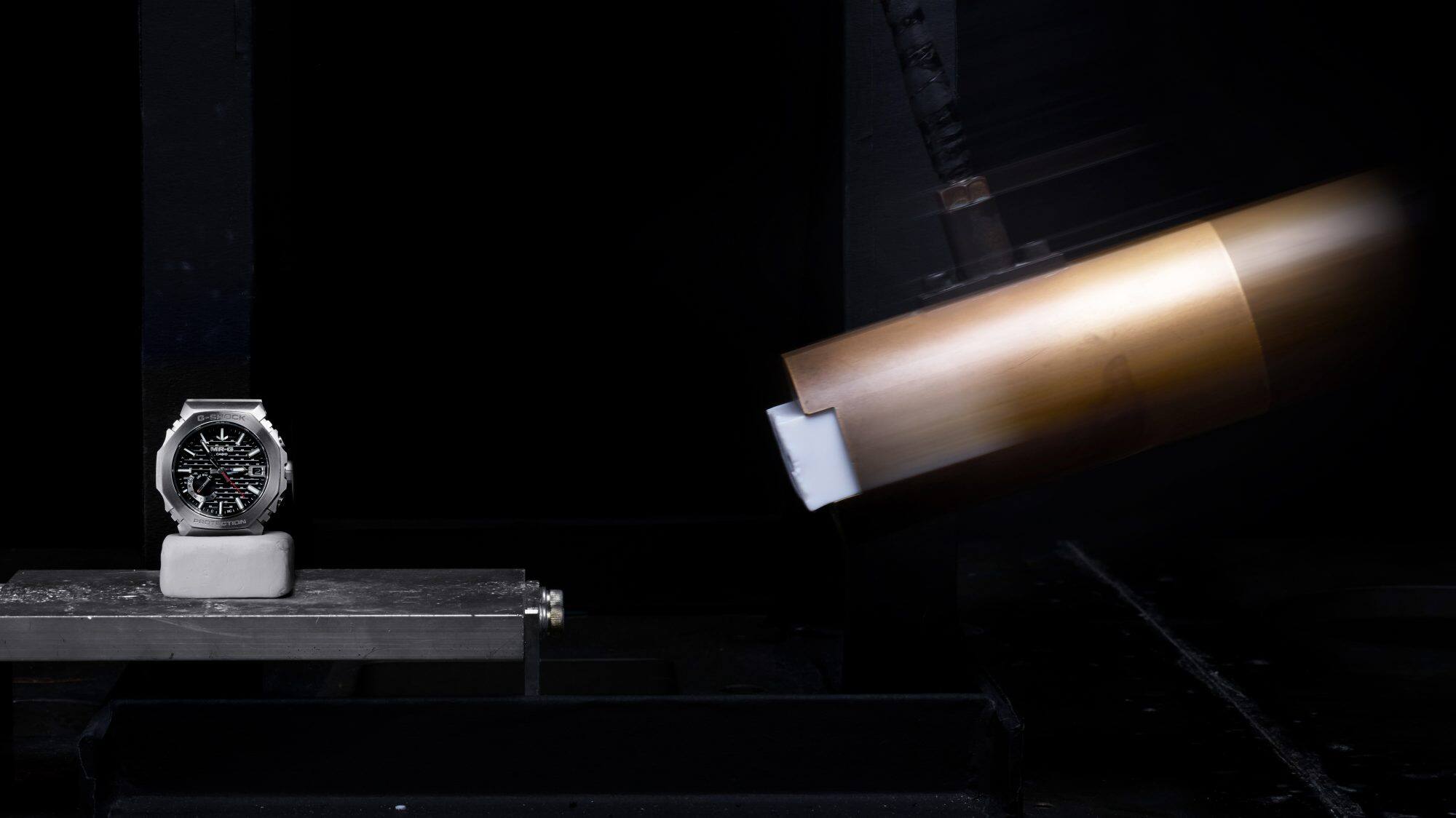

Electrostatic testing

An electrostatic discharge gun is applied to a watch to assess its resistance to static electricity, testing conducted for all watches at the development stage. The human body is said to build up charges of over 10,000 volts during winter. While taking into consideration environmental factors and referencing International Electrotechnical Commission (IEC) standards, Casio-specific margins are set for applied voltage, making the assessments more extreme. The discharge gun applies specified voltages to test for any malfunction or damage each might cause.

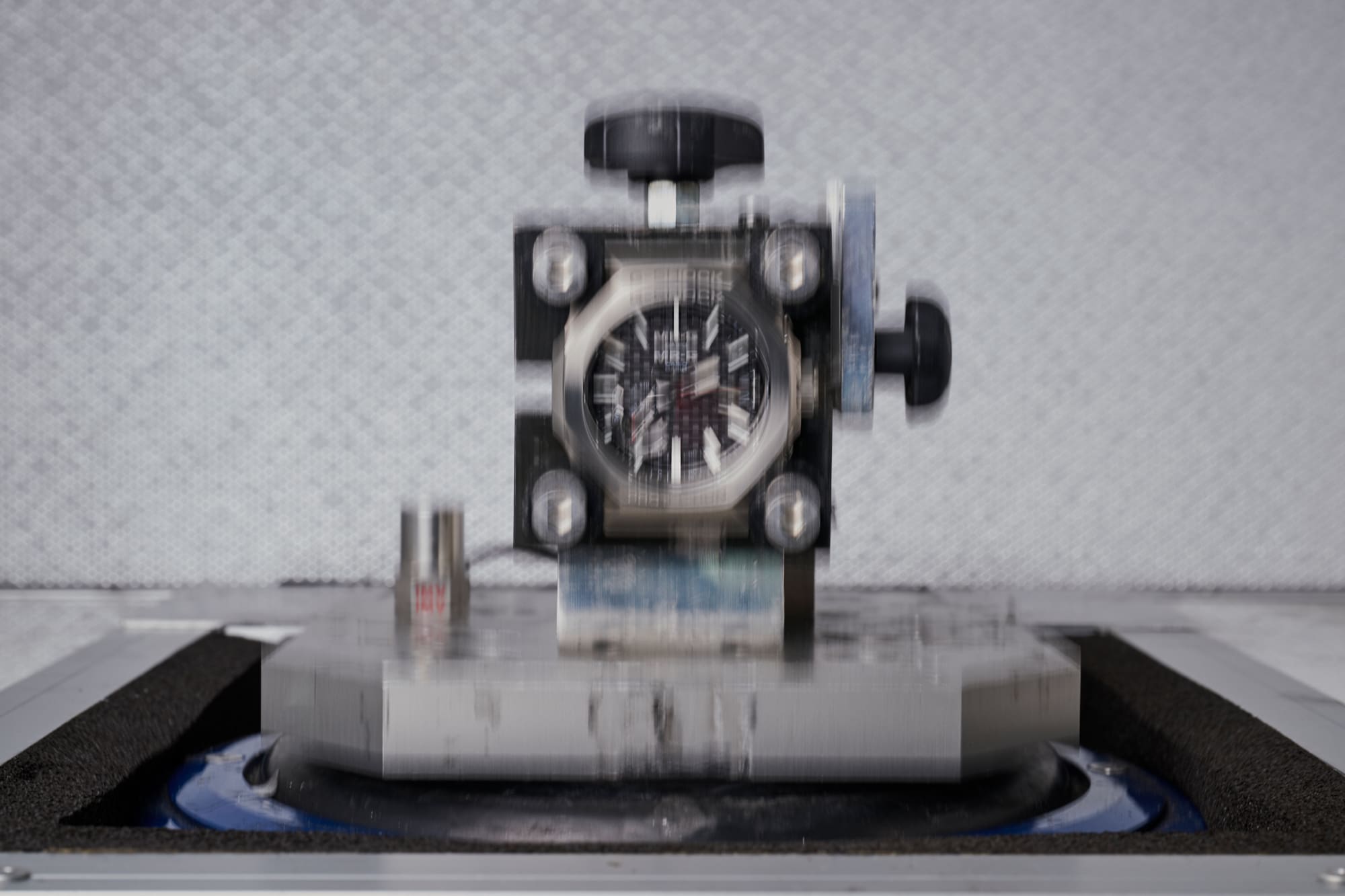

Vibration-resistance testing

High-speed vibration is applied to a securely affixed watch to test its vibration resistance. The shaking is so intense it can be felt on other floors of the building.

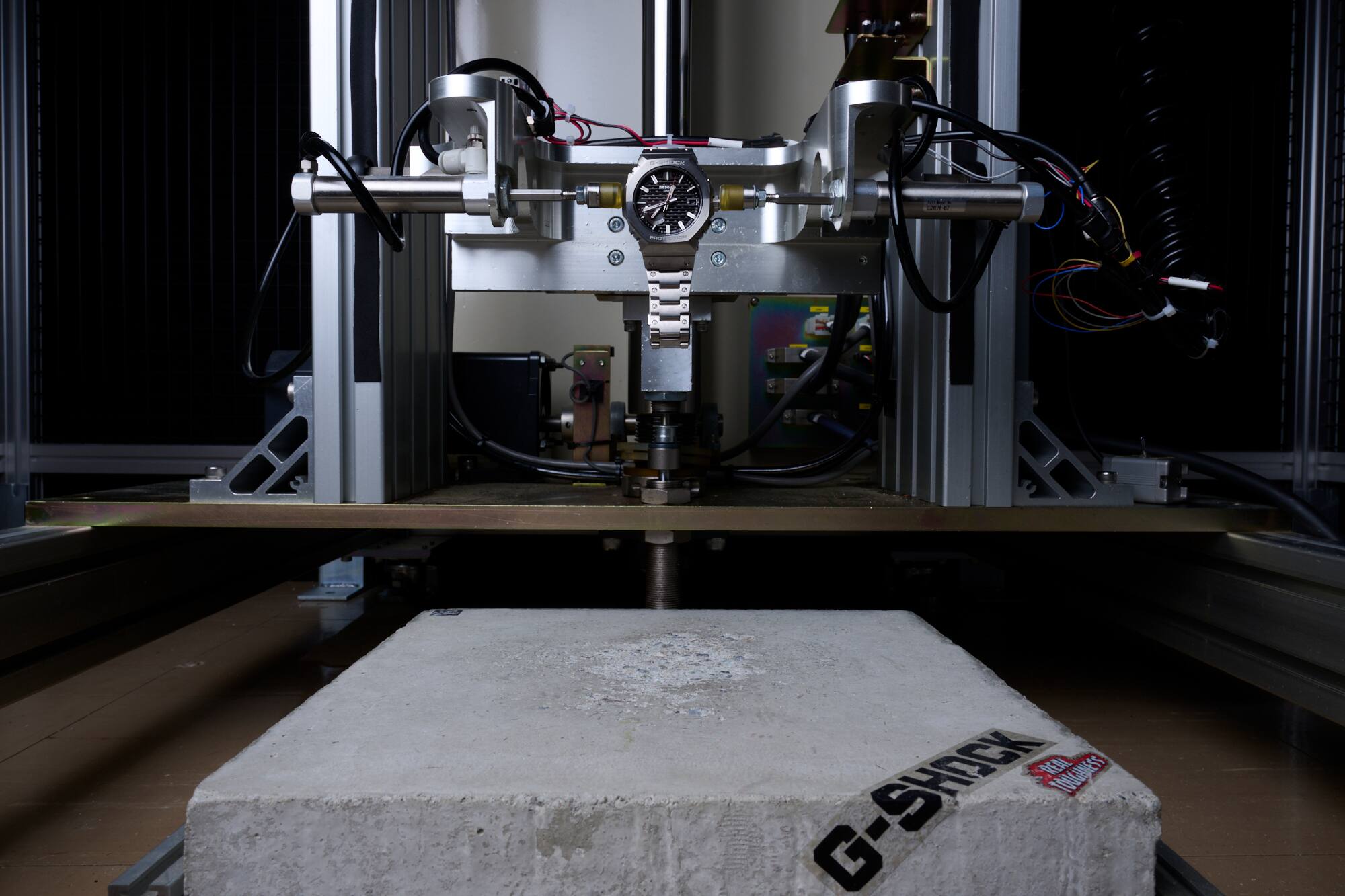

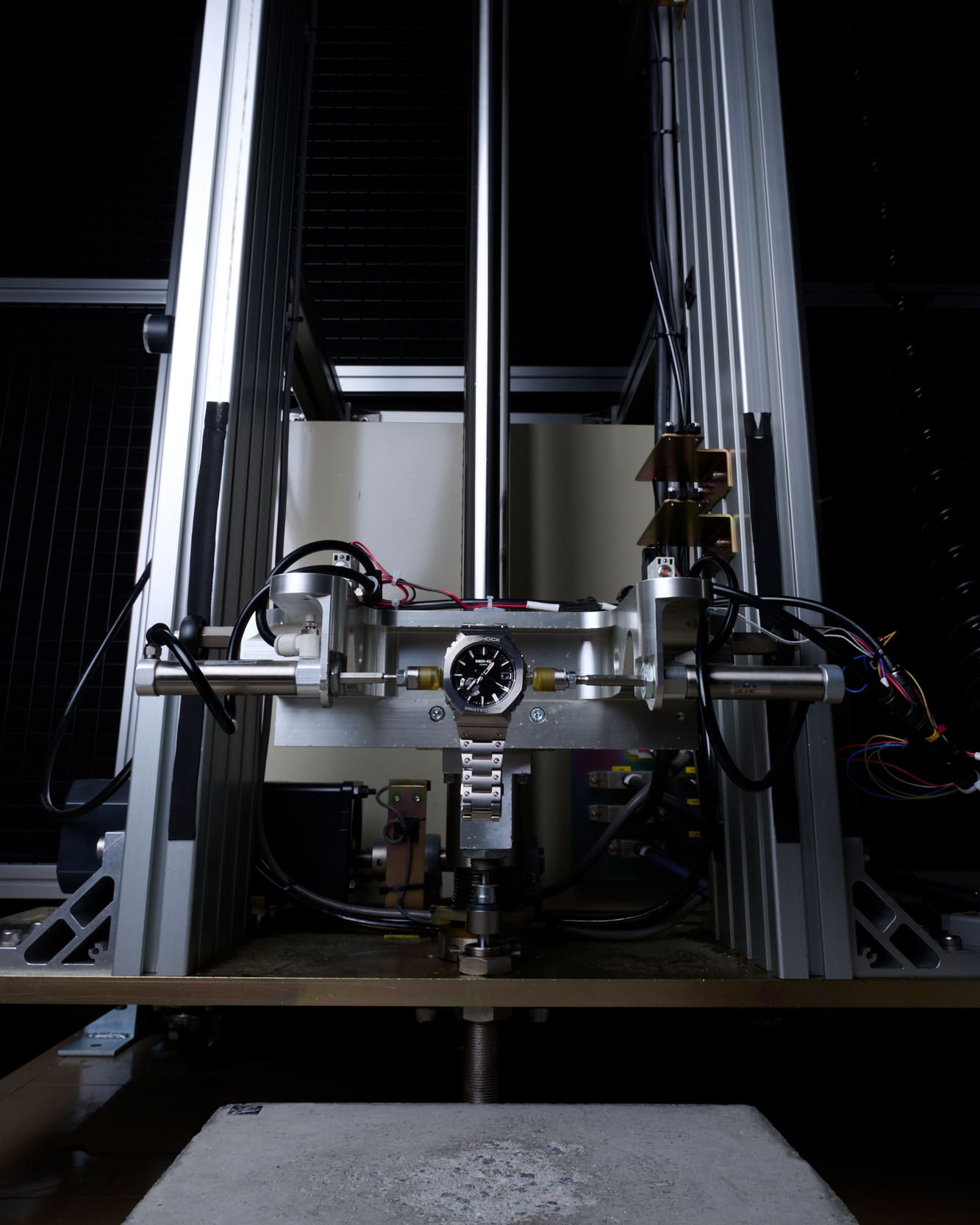

Drop-impact testing

Shock resistance is assessed with Casio specific margins added to the values from the International Organization for Standardization (ISO), such as height, number of drops, and direction, using accelerated drop testing equipment developed specifically for G-SHOCK. Watches are secured to a bar and accelerated with a spring mechanism. After being dropped from above, they are released just before crashing into the floor, with the impact applying intense shock.

Water-resistance testing

As in drop-impact testing, Casio adds its own margins to ISO standards for water resistance in watches. Beyond this, a wide range of related water-resistance testing is performed, including underwater button durability tests for diver’s watches in both pressurized and non-pressurized forms.

Over 200 assessment specifications

The assessment specifications are continually being updated in accordance with evolving product concepts. A laboratory wall chart outlines the many categories comprising the Casio approach of aggressive quality assurance, from harsh-sounding chemical resistance testing to artificial sweat immersion tests based on samples of actual human sweat to assess corrosion resistance.